The Southeast Dairy Business Innovation Initiative (SDBII) is proud to serve Southeastern dairy business and even more so, proud of the impacts our award recipients have reported since receiving their grant awards. See below for testimonials directly from award recipients.

“The SDBII grant program has had a significant impact on our business. The margins on the dairy business and cheese making business are very small. Boxcarr Handmade Cheese would not have been able to purchase this equipment without the Grants. The equipment makes it easier for us to do our job and helps our employees. The staff from our local NC Extension staff to the Univ of Tennessee staff that administer the program understand our needs and are always ready to help.” – Boxcarr Handmade Cheese, 2023 Farm Infrastructure Improvement Grant Recipient

“As mentioned above, this grant has had a tremendous impact on our farm. It has helped us be more efficient and produce high quality milk. We are very grateful for this opportunity. The SDBII team was very helpful in all aspects of the grant from writing to implementation.” – Davis Brothers Dairy, 2023 Farm Infrastructure Improvement Grant Recipient

“The SDBII grant program has had a significant positive impact on our business performance. Since implementation, our annual sales have increased from $8,747,879 to $9,800,948, reflecting stronger revenue and improved operational efficiency. Over the same period, milk production has grown from 36,607,993 to 38,233,594 pounds, indicating better productivity and throughput. At the same time, our somatic cell count per milliliter of milk has dropped from 202 to 77, demonstrating a substantial improvement in milk quality and herd health. Together, these changes show how the grant-supported investments have strengthened both our profitability and product quality, providing a clear success story for the SDBII program.” – Godfrey Dairy Farm, 2023 Farm Infrastructure Improvement Grant Recipient

“The SDBII grant program has positively impacted our family business. After the addition of the free stall barn and 4,000-gallon milk tank, our gross revenue has grown almost $1,000,000 annually. This increase in revenue has given us margin after the bills are paid, and that is a great feeling. This has given our family motivation to continue in the dairy business and grow to provide more high-quality milk to the public. We are incredibly thankful to have been selected.” – Huffard Dairy Farms, 2023 Farm Infrastructure Improvement Grant Recipient

“The SDBII grant program had a profound impact on our farm, providing economic resilience and stability. Implementation of this project has allowed our farm to focus on animal welfare, overall farm profitability, and labor efficiency. We are so appreciative of the SDBII program and team!” – Tester Dairy Farm, 2023 Farm Infrastructure Improvement Grant Recipient

“The SDBII has helped me with vital resources that I needed to grow my business. Through the educational programs I have gained valuable insight into the dairy industry that will help make decisions for the future of my operation. The equipment grants have helped me acquire equipment that I wouldn’t have been able to afford until years down the road.” – Rafting Goat Dairy, 2023 Farm Infrastructure Improvement Grant Recipient

“This grant helped our farm make an investment in technology that allows a small farm to manage operations like a large diary. Assistance with the large expense of purchasing robotic feed pushers has increased production and reduced operating costs.” – Paulson Family Farm, 2023 Farm Infrastructure Improvement Grant Recipient

“This grant allowed our farm to enhance our on-farm manure management plan significantly. The financial strain of the prices that new equipment poses to farms is a huge challenge and burden to many small family farms. For our operation, this grant allowed up to choose the appropriate system upgrade that we needed to significantly change how we manage the manure on the farm. Our old system was over 20 years old and cost us more money to maintain.” – Perk Farm Organic Dairy, 2023 Farm Infrastructure Improvement Grant Recipient

“Most important impact of this project is the improved mental and physical state for our family. The reduced time in the milk parlor improved our physical state. But mentally as well. Mental is huge and less time in the parlor each day improves the mental state greatly.” – Waller Dairy, 2023 Farm Infrastructure Improvement Grant Recipient

“The SBDII Grant allowed us to improve cow comfort for our milking herd and increase milk quality. The grant funds allowed us to do upgrades that we couldn’t financially swing on our own.” – WRF Dairy, 2023 Farm Infrastructure Improvement Grant Recipient

“The SDBII grant program has helped our dairy to be able to invest in equipment we would not have initially invested in. It has helped us to be more efficient with labor and improve milk quality. Without this program we would not have invested in the PLC at this time.” – Harrison Dairy, 2024 Farm Infrastructure Improvement Grant Recipient

“This grant allowed our farm to invest in infrastructure that greatly impacted the comfort of our cows and in turn our bottom line. These types of investments are huge challenges to small farms because of the large upfront costs, and this grant bridged that gap. We are so grateful for the opportunity and those who made the SDBII grant possible.” – Paulson Family Farm, 2024 Farm Infrastructure Improvement Grant Recipient

“This SBDII grant program is a great thing to give some extra help and a little nudge in the right direction to move forward with some projects that otherwise may not get done due to rising prices and milk price variation.” – H and H Dairy, 2024 Farm Infrastructure Improvement Grant Recipient

“Celebrity Dairy developed over 37+ years as a self-funded small goat cheese dairy. Husband Brit Pfann was a suburban boy from Pittsburgh, PA with no agricultural background, and wife Fleming Pfann grew up on a small NC tobacco farm before the availability of electricity. Neither had previous dairy experience. What began hand-milking a few goats soon became a bucket milking operation, but stasis prevailed, and we never moved on to a mechanized pipeline dairy operation. We had always self-funded our facility, and only recently became aware of USDA grant programs for small scale farming. Knowing that our effort was no longer sustainable, but hopeful of helping another generation to keep the dairy in business, we decided to apply for this grant to make a generational transfer an economically feasible reality. Our facility upgrade has lagged its proposed schedule – first from USDA grant disruptions, but to a greater extent long delay in importing French goat stanchions, and finally from the reality that we had to work with the time availability of one of the very few dairy equipment businesses still operating in North Carolina. The silver lining of these delays is that the bulk of the pipeline installation work ended up being done during our goat herd’s seasonal dry period, so that the parlor tear down and rebuild has occurred while the milking parlor was not in use.” – Celebrity Dairy, 2024 Farm Infrastructure Improvement Grant Recipient

“We continue to be incredibly grateful for having received this grant. The fans have been an absolute blessing and have improved the quality of life of the cows, AND the working conditions of the employees. It is delightful on a hot summer day to feel the breeze from the fans blowing right into the milking parlor; this was an unexpected bonus!! As stated in the project impact section, given the unprecedented health challenges that we faced with our herd this past year because of Hurricane Helene, I cannot imagine how our animals would have fared if we had not been able to install these fans. We were unable to improve the quality of their feed but thank God, we were able to reduce the heat stress that they had to deal with. Thank you, SDBII!!!” – Cresthaven Farms, 2024 Farm Infrastructure Improvement Grant Recipient

“Had it not been for this grant opportunity, we would not have been able to afford the materials to complete this project. This increases our pregnancy rate on heifers, thus reducing time to first calf, reducing feed and manure management by thirty days per heifer.” – VanDerHyde Dairy, 2024 Farm Infrastructure Improvement Grant Recipient

“The SDBII Grant Program has been an integral part of our business, helping us grow and expand operations. Not only do they help with planning and funding for critical projects, but they also provide plenty of educational content and programming that is helpful to our business.” – Sweetwater Valley Farms, 2021 Specialty Processing Equipment Grant Recipient

“I think it is not unreasonable to say that without SDBII, Sequatchie Cove Creamery would be a very different business, perhaps it would not be a business at all. The equipment is an essential and important part of how SCC has been supported, but it is the community and learning which has made the largest impact. These intangible aspects of the program created hope for the business during a dark time and has provided an opportunity when no other was available.” – Sequatchie Cove Creamery, 2021 Specialty Processing Equipment Grant Recipient

“I think the success of small-scale dairies rests on value-added products that can be made in on-farm creameries. The SDBII grant program helps make these kinds of innovations and expansions possible for so many farmers who cannot / should not take out huge loans to expand in this way. The grant allows for farmers to try and change their business in a lower risk way: this is a huge benefit for an industry where the margins are so small, and the financial risk is very high. The resources and support from the SDBII team are also huge – we always felt supported and understood by the UT team.” – Grass Roots Farm & Dairy, 2021 Specialty Processing Equipment Grant Recipient

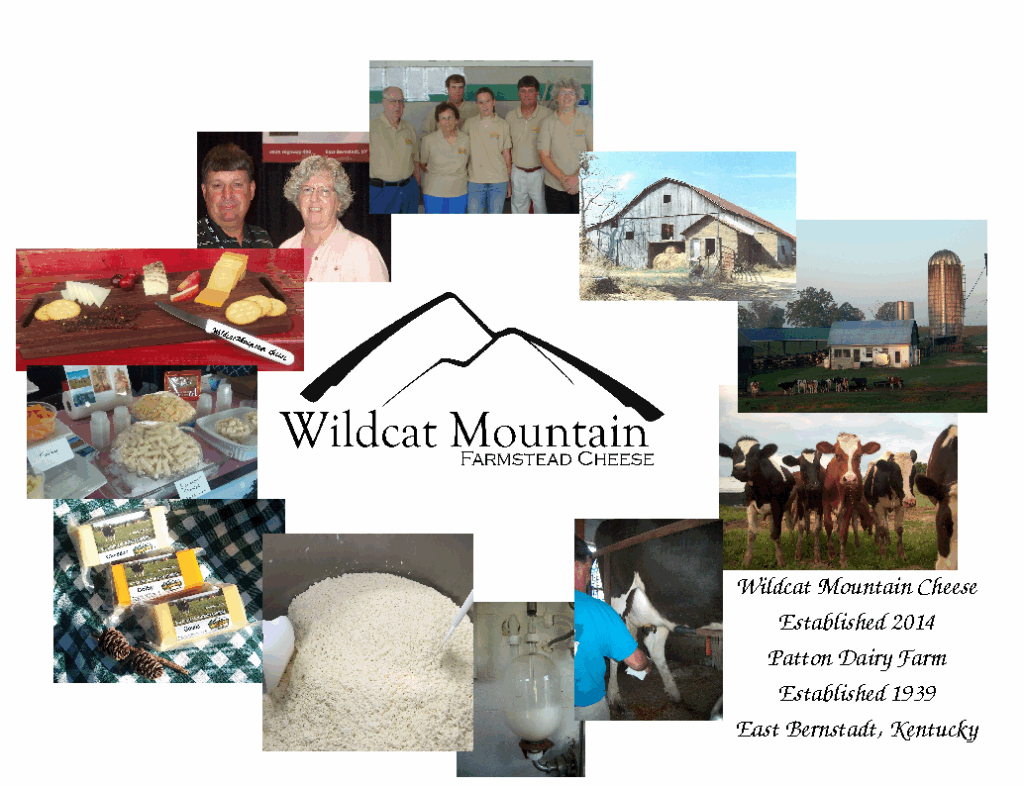

“Although we were already established in producing on-farm value added dairy products and were successful, by purchasing additional equipment with the grant, we were able to expand cheese product offerings and improve our work productivity. As a family farm with limited resources, especially labor, the grant was instrumental in helping us to achieve the goal of continuing dairy farming as a family, especially as farm profit margins are smaller and often non-existent.” – Wildcat Mountain Cheese, 2021 Specialty Processing Equipment Grant Recipient

“The SDBII grant program gave us the confidence and foundation to move forward with value-added dairy plans that once felt out of reach. It helped us build our brand, connect with customers, and better understand processing goals. Because of this program, we are positioned for long-term growth and a more sustainable future for our family farm.” – Horse Creek Farms, 2021 Specialty Processing Equipment Grant Recipient

“This SDBII Grant had a huge impact on Boxcarr Handmade cheese because of the size of it. Many pieces for specialized equipment were purchased and many other smaller cheese production items like the molds and cutting knives.” – Boxcarr Handmade Cheese, 2021 Specialty Processing Equipment Grant Recipient

“Where do I start…. the SDBII grant has helped us stretch our dollars to meet the needs of our small business. Until I was able to get a bigger ice cream churn, I was spending many late nights making ice cream to just keep up with our customers’ needs. With the use of this grant, we have been able to increase our customer base by providing more flavors of ice cream and provide them with a wholesome dairy product, that is made fresh and made local.” – Rowlett’s Milkhouse Creamery, 2021 Specialty Processing Equipment Grant Recipient

“The SBDII grant was very helpful to our business in allowing us to ramp up production and sales of ice cream at our on-farm store with proper cold chain technology and professional packaging. It would have taken us years to get all those pieces sourced, purchased and put into service without the grant support. Our ice cream is all sold through our on-farm store. It was our on-farm store during Covid and then again following the devastation of Hurricane Helene that bounced back the fastest due to the local community stepping up and supporting our operation during these difficult times. Great ice cream makes that support easy to justify!” – Looking Glass Creamery, 2021 Specialty Processing Equipment Grant Recipient

“It is hard to quantify right now how much of an effect the grant will have on our business. That is, did the grant propel us 5 years into the future, or 10? Paradoxically the disastrous post-Helene year we have just gone through, in conjunction with the capital upgrades we were able to make thanks to the grant, should position us to make significant qualitative and financial progress in the coming year. We will still struggle, particularly around employees, but the slow, steady progress we had been making looks to be turbocharged for the foreseeable future.” – French Broad Creamery, 2022 Specialty Processing Equipment Grant Recipient

“It is difficult to fully express how impactful the SDBII grant has been for Milky Way Farm. This support allowed us to upgrade and modernize our creamery in ways that would not have been possible on our own. With the new automated control system, we are now able to process more milk with greater efficiency, produce a more consistent and higher-quality product, and significantly strengthen food safety across all creamery operations. In addition, the improvements have made our work environment safer and more manageable for our employees by reducing the physical demands and specialized labor previously required. These advancements not only support our current operations but also position Milky Way Farm for continued growth and long-term sustainability as one of the few remaining dairies in South Carolina. The grant has had a transformative, lasting impact on our business and our ability to serve customers throughout the state.” – Milky Way Jersey Farms, 2022 Specialty Processing Equipment Grant

“The SBDII grant has been instrumental in helping us expand and enhance our yogurt business. With the support of this grant, we were able to invest in new machinery that not only accelerates production and reduces production times but also allows us to offer yogurt in a variety of sizes beyond our original 32-ounce bottles. This expansion has enabled us to hire four additional team members and double our production hours of 8 to 16 hours per day. Our production capacity has significantly increased, allowing us to produce up to 2,000 liters of yogurt, compared to the 800 liters we were previously able to make. As a result of these improvements, we anticipate our revenue growing from $900,000 in 2024 to $1.2 million in 2025, with continued growth projected to reach $4 million by 2028. The grant has not only strengthened our operations but also positioned our business for long-term success and scalability.” – Quesos Vaca Negra, 2022 Specialty Processing Equipment Grant Recipient

“Without the help of the SBDII grant, our current business of operations would have been 5-7 years out from being able to feasibly move into our new equipment. Our growth was exceeding our capacity and this grant allowed us to purchase more efficient equipment that has resulted in higher production volume more efficiently and increased our profit margins while maintaining our quality.” – Riverbend Creamery, 2022 Specialty Processing Equipment Grant Recipient

“The grant has helped us grow in long term thinking in the dairy space. As I mentioned above, growing a business is a long-term commitment. The grant offered us the funds to start the process of developing a multi-million dollar per year CPG. We are committed to continuing this process and hope to continue a long-term partnership with SDBII in this development. It gave us the confidence to take steps in developing new methods for delivering ice cream to customers and commitment to the quality of our product.” – Irvey’s Ice Cream Company, 2023 Specialty Processing Equipment Grant Recipient

“The SDBII grant program has been incredible for our business. At the end of 2024 we were completely out of additional freezer space at our production space and our satellite stores only had reach in freezers and no walk ins. This made us prioritize producing 3-gallon buckets and not pints, cakes, and novelties which are profitable for us. At the end of 2025 not only do we have 2 additional stores, but with each shop having a walk-in freezer for storage and merchandising freezers for pints and cakes we are able to produce, store, and see twice as much ice cream as before. The expansion we’ve been able to do in 2025 has set us up for yet another year of growth in 2026 as we look to move our production space offsite into a 6,000sf facility in midtown Wilmington.” – Boombalattis, 2024 Specialty Processing Equipment Grant Recipient

“The SDBII grant program has been transformative for our farm’s ice cream operation. With support from this program, we have been able to invest in larger, more efficient equipment that directly increases our production capacity while maintaining the high quality our customers expect. This has allowed us to meet growing demand and operate more sustainably by improving efficiency and minimizing waste. The grant has not only helped our business grow but has also strengthened our connection to our local community by allowing us to serve more customers, support local agriculture, and showcase the value of farm-made dairy products. This investment has positioned our business for long-term success and demonstrated how targeted funding can make a meaningful difference for small, farm-based food producers.” – Green Acres Creamery, 2024 Specialty Processing Equipment Grant Recipient

“This project represents the second Dairy Business Innovation Grant awarded to Milky Way Farm, and together these investments have played a critical role in sustaining and growing our dairy operation. As a value-added dairy, bottling and selling our own milk is essential to our business model—without on-farm processing and direct sales, Milky Way Farm would not be able to remain in the dairy business. This grant enabled us to scale our creamery operations more quickly and efficiently by investing in automation that improves reliability, labor efficiency, and product consistency. The resulting gains have strengthened our ability to serve a growing network of retail and distribution partners while maintaining high food safety and quality standards. Beyond operational improvements, the impact of this grant extends directly to workforce and community development. Increased efficiency and stability in the creamery created the opportunity to bring family members back into the business and to hire local employees in full-time positions. These jobs support rural economic activity and help ensure the long-term viability of a family-owned dairy operation. Overall, this grant investment has accelerated growth, reduced operational risk, and reinforced Milky Way Farm’s commitment to value-added agriculture. The continued support through the Dairy Business Innovation Grant program has allowed our farm not only to survive, but to grow, innovate, and contribute meaningfully to the local agricultural economy.” – Milky Way Jersey Farm, 2024 Specialty Processing Equipment Grant Recipient

“We are very grateful for the SDBII grant program as we have been able to increase efficiency in the plant. Wishing we had had the opportunities years ago of these grants, we have been able to purchase a larger filler, labeler, butter churn, an updated separator and preheater and have increased our products. What once took over 12-13 hours 5 days a week, now can be processed in 8 hours or less 3 days weekly. If volume needs to be increased, the 4th day would be able to handle it in approximately 4 hours. We presently bottle what we did in 5 days in three, saving in chemical used to wash up (approximately $65/day) and time sanitizing and washup (2.25 hours x 2 persons/day) and the extra hours to process (7-8 hrs/ day @ 3 people =$50/hr or $350-400 savings). So instead of 4.5 days of 9-10 hr daily we are 3.5 day of 9-11 hours. We bottle buttermilk on Tues morning and then done.” – Southern Swiss Dairy, 2024 Specialty Processing Equipment Grant Recipient

“The money we received to cover the lawyer fees to set up a transition plan is an integral part of the ability for us to be able to transition the dairy to the next generation.” – Brush Creek Swiss Farms, 2021 Dairy Business Planning Grant Recipient

“Boxcarr Handmade Cheese is a small family business, siblings Samantha and Austin Genke and Austins wife Dani. There are 5 other employees, mostly part-time. Margins on the farming and cheese making side of the business are very tight. With the SDBII Grants we can hire professional help to advise on our Food Safety program. The grants help to purchase equipment that improves the welfare of the goats, improves the farming and cheese making side of the business and make the jobs of the owners and employees better.” – Boxcarr Handmade Cheese, 2023 Dairy Business Planning Grant Recipient

“The grant program has been a valuable tool for our dairy and me personally. Some of the programs it funded would probably never have been considered without the grant and the assistance of the personnel involved.” – Carmichael Dairy, 2023 Dairy Business Planning Grant Recipient